- Overview

- Recommended Products

Product introduction:

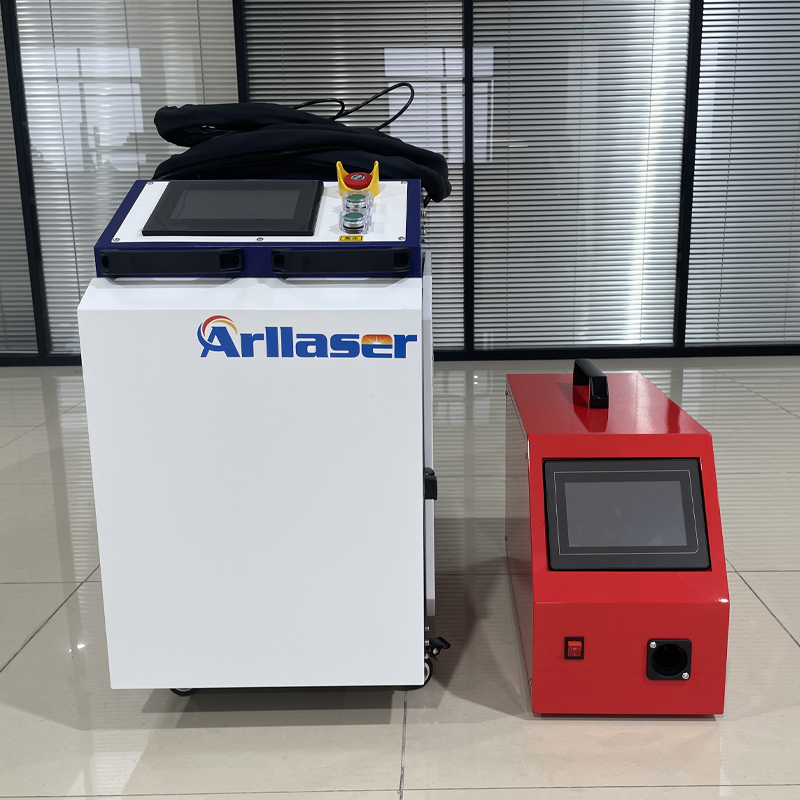

Handheld laser welding machines are becoming increasingly popular due to their versatility and ease of use. These machines are designed to be lightweight and portable, making them ideal for on-site repairs and small-scale manufacturing tasks.

Equipped with touch-screen controllers, handheld laser welders are easy to operate even for users with no welding experience. Beginners can learn to use them within a few hours, unlike traditional welding methods such as MMA, TIG, and MIG, which typically require years of practice.

When evaluating laser welder pricing, handheld laser welding machines offer a cost-effective solution for many applications. Our machines feature high-power laser sources with power ranges from 1500W to 3000W. A 1500W portable fiber laser welder can join metal parts up to 4 mm thick, a 2000W handheld laser welder can weld metal up to 5 mm thick, and a 3000W portable laser welder can perform single-sided welding on metal up to 6–8 mm thick. With double-sided welding, it can handle metal parts twice as thick.

Key Advantages:

1. Easy to Use: Master laser welding technology in just 30 minutes. If you can use a hot glue gun, you can operate a laser welder. Quick and simple setup.

2. Excellent Quality and Consistency: Low heat input minimizes part deformation and ensures high-quality welds. Built-in preset functions guarantee consistent welding results.

3. Enhanced Safety and Comfort: Minimal spatter reduces the need for heavy protective clothing. With lower heat output, only lightweight gloves are required.

4. Wide Material Compatibility: Suitable for aluminum, copper, steel, stainless steel, and titanium.

5. Low Power Consumption: Lower energy use makes it more efficient and cost-effective.

Applications:

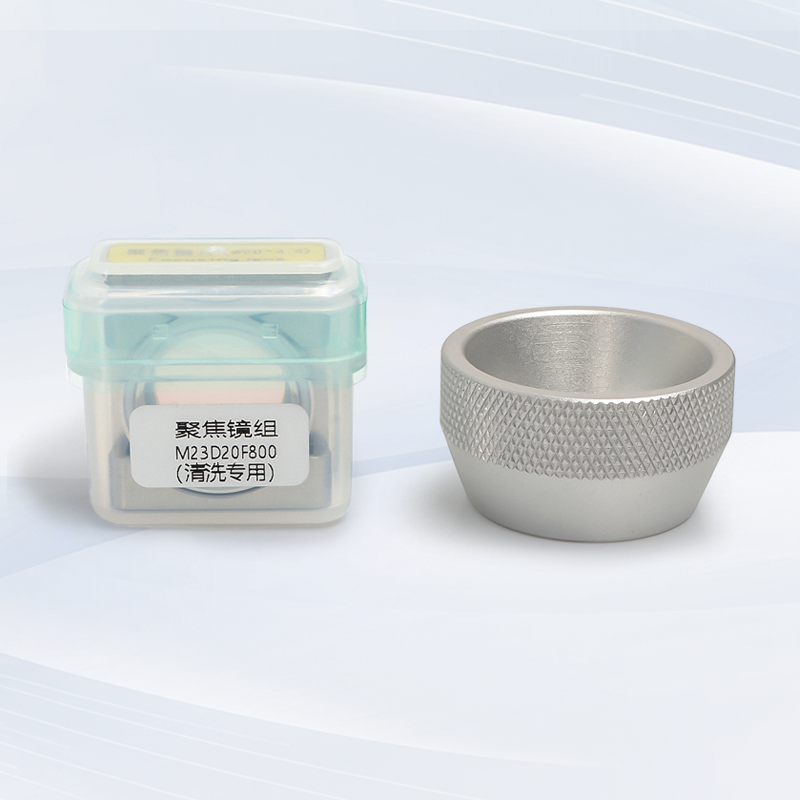

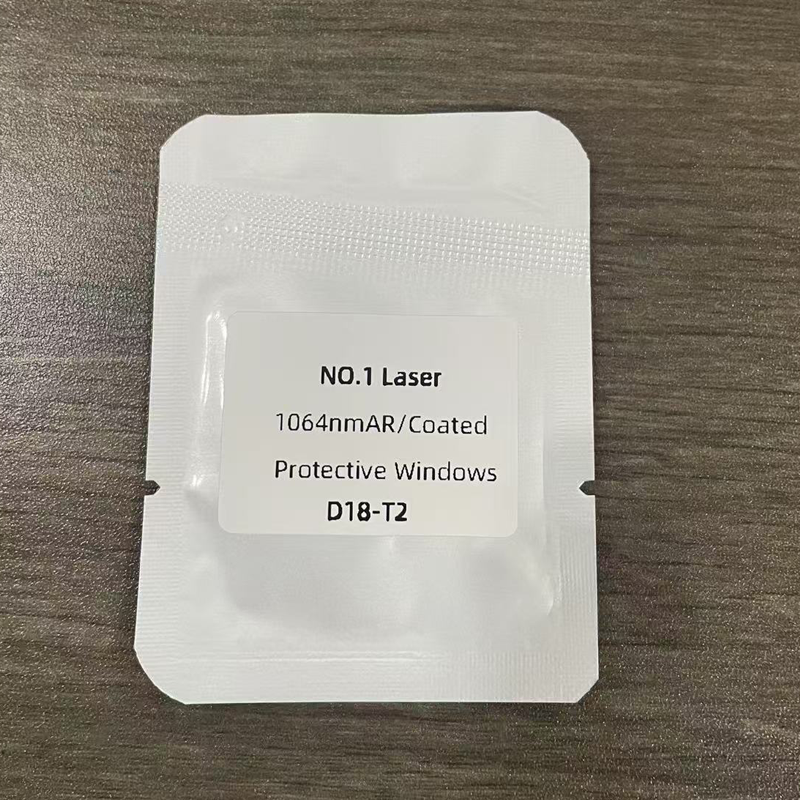

This 4-in-1 laser welding machine features cleaning, cutting, and welding modes. In the field of metal processing and manufacturing, it can efficiently weld and cut various types of metals — including stainless steel, aluminum, and copper — to produce a wide range of metal components and products.

Specifications:

Technical Parameters | |||

Model |

HC-1500S |

HC-2000S |

HC-3000S |

Laser Source |

BWT/MAX/RAYCUS |

||

Laser Power |

1500W |

2000W |

3000W |

Power Adjustment Range |

10-100% |

||

Laser Wavelength |

1080±10nm |

||

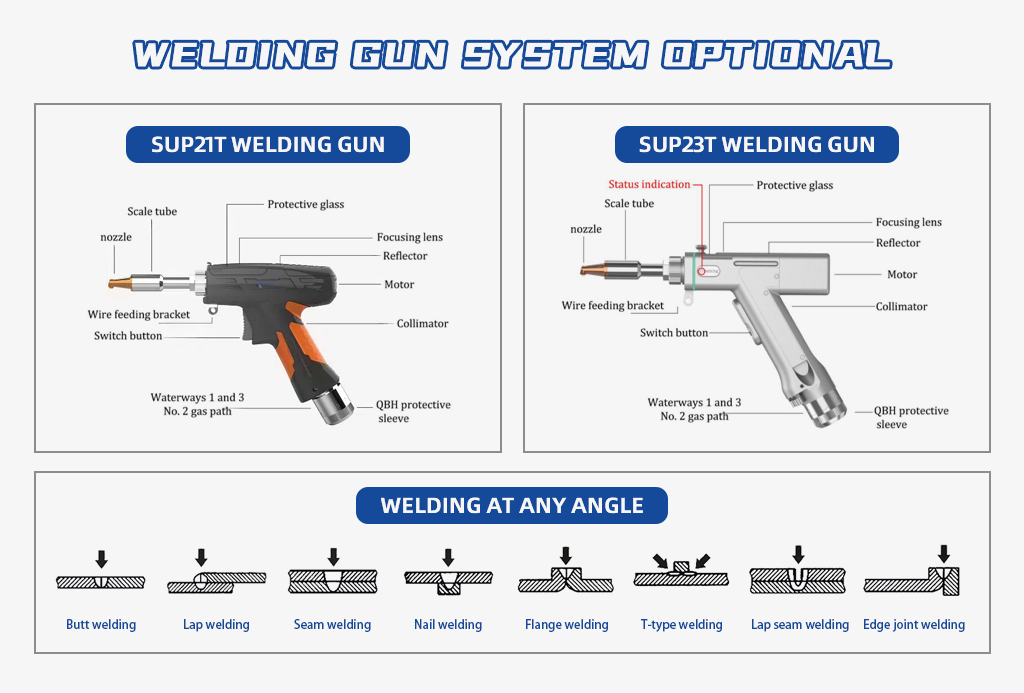

Welding Gun System |

SUP22C |

||

Scan Width |

10-300mm |

||

Cooling Method |

Water Cooling |

||

Optical Cable Length |

10m |

||

Operating Voltage |

AC220V 50/60Hz |

AC380V 50/60Hz |

|

Ambient Temperature |

10~45 ℃ |

||

Environment Humidity |

10%-85% |

||