- Overview

- Recommended Products

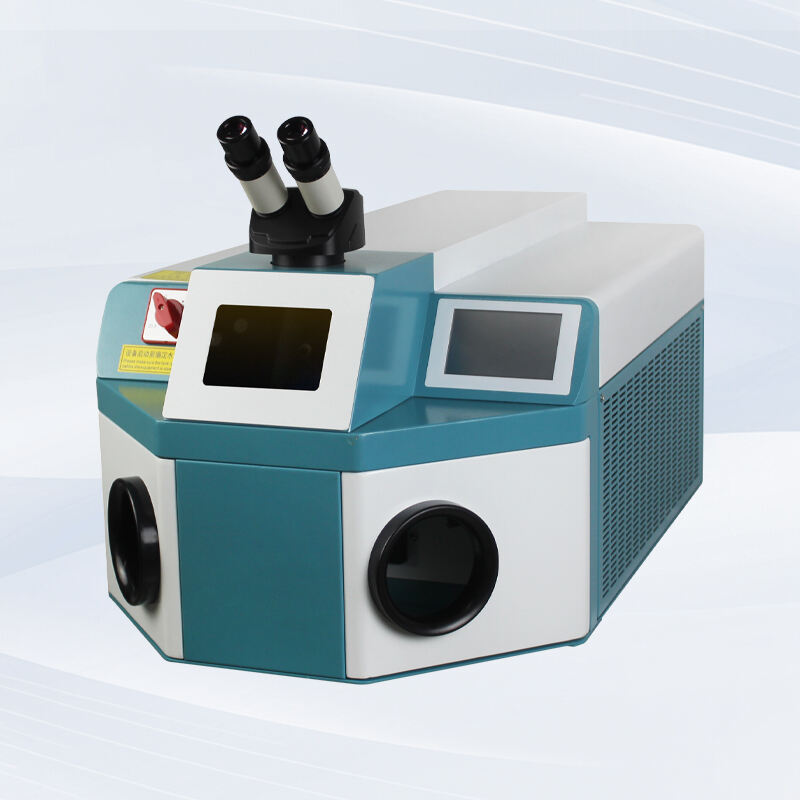

Product introduction:

The Laser Jewelry Spot Welding Machine is mainly used for hole repairing, sand hole welding, and precision restoration of gold and silver jewelry. As one of the key applications of laser material processing technology, laser spot welding is a heat conduction-based process—the laser beam irradiates and heats the workpiece surface, and the heat diffuses inward through conduction. By precisely controlling parameters such as laser pulse width, energy, peak power, and repetition frequency, the material locally melts to form a stable molten pool and achieve firm, precise welds.

With its high welding precision, minimal heat-affected zone, smooth and aesthetic weld seams, and user-friendly operation, the machine is widely used in gold and silver jewelry manufacturing, precision electronics, micro components, and fine repair applications, providing an efficient and reliable solution for high-end jewelry fabrication and micro welding industries.

Key Advantages:

1. Improved by the introduction of German advanced technology,series of products using ergonomic design, and the use of high-quality accessories production, the whole machine is more reliable, more durable;

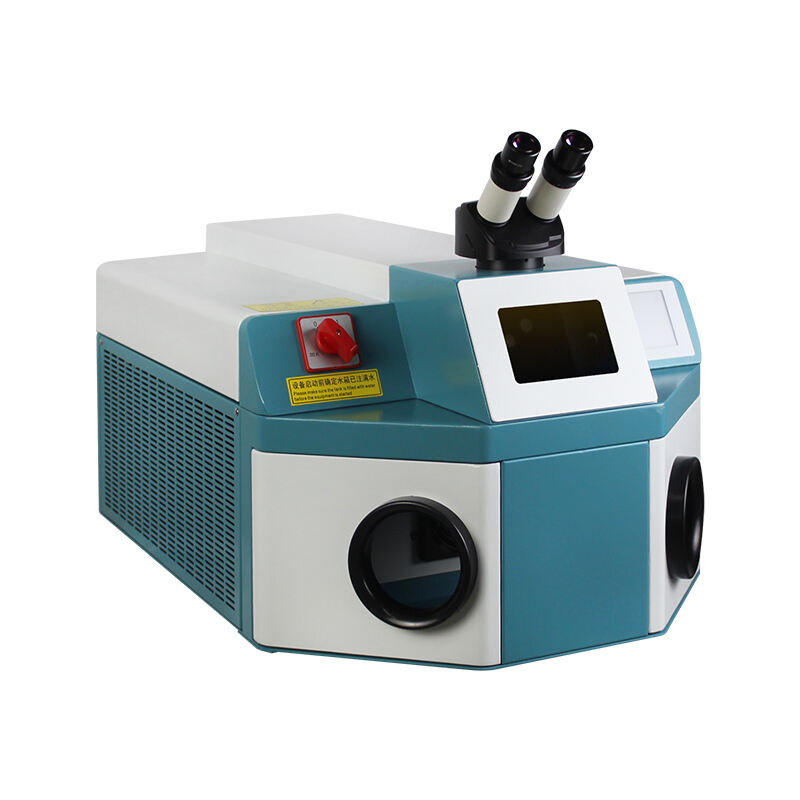

2. Compact structure, can be placed on the table, easy to handle;

3. Easy operation, good welding effect, stable equipment, low failure rate;

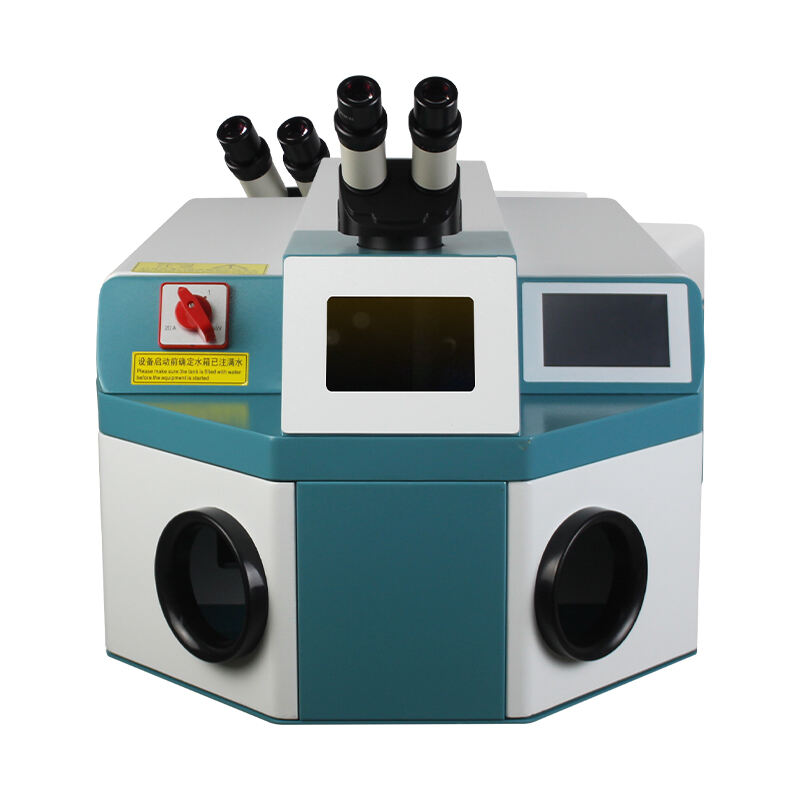

4. Special microscope observation system with cross cursor with high-speed electronic light filter to protect the operator's eyes.

Applications:

It can be used for 18K gold, 925 silver, dentures, watch and glasses repair, spot welding, repair of welding porosity, and gold-inlaid jade welding, etc. Applicable to stainless steel, copper, gold, silver, K gold, and other metals and alloys. Mainly used in jewelry, electronic components, communications, crafts, and other industries. An essential welding and repair tool for jewelry workshops, gold and silver stores, watch and eyewear maintenance shops, as well as scientific research laboratories in colleges and universities.

Specifications:

Technical Parameters | |

Laser type |

ND:YAG |

Power adjustable |

1%-100% |

Wave length |

1064nm |

Maximum laser output power |

200W |

Pulse width |

0.1-20ms |

Weld depth |

0.1mm-2.5mm |

Spot size adjustable range |

0.1-3.0mm |

Control system |

Single chip microcomputer |

Laser welding frequency during combo |

1.0-30Hz |

Rated power |

5kw |

Electricity demand |

220V±5%/50Hz/30A |

Dimension(L*W*H) |

850*500*520 |

Weight |

70kg |