- Overview

- Recommended Products

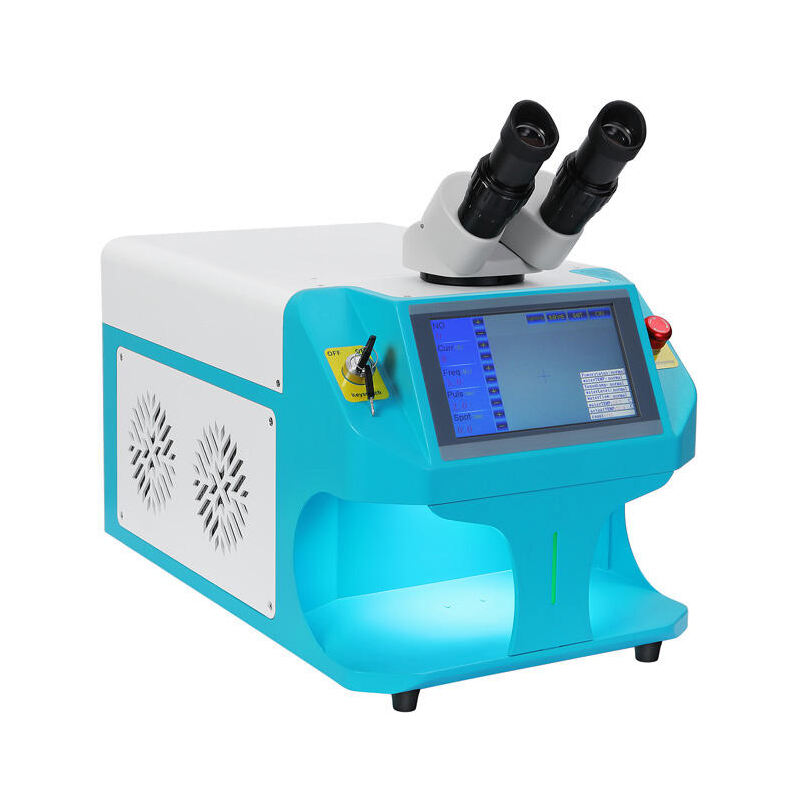

Product introduction:

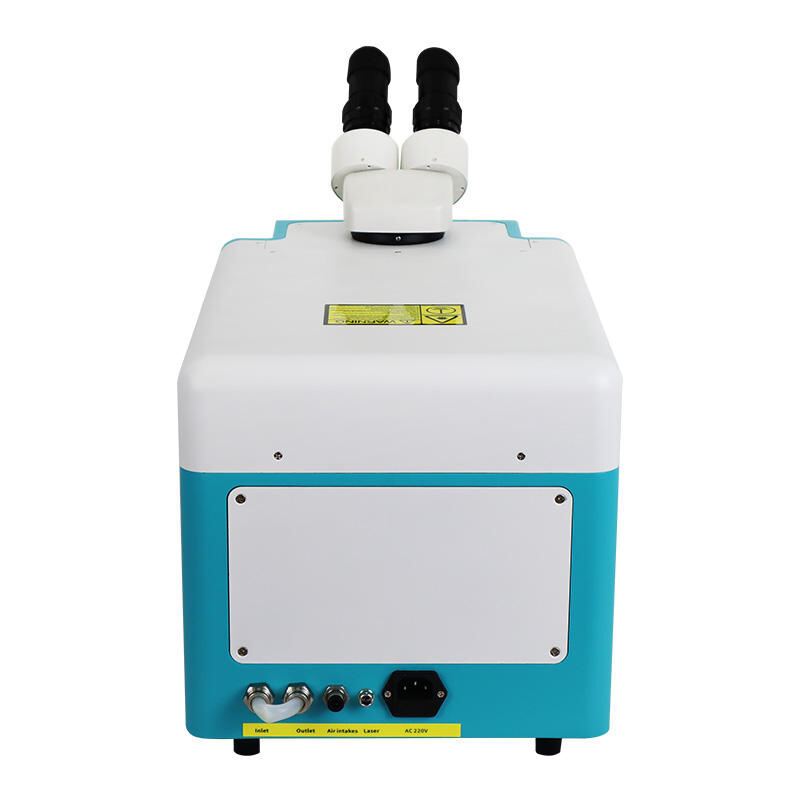

Micro laser spot welding machine is composed of YAG pulse laser, laser power supply, imported optical system, built-in integrated water cooler,CCD observation system, etc. Desktop equipment, small size, light weight, powerful.

Key Advantages:

1. Simple operation, stable and reliable;

2. Compact and portable, better space saving;

3. High welding quality, beautiful gap, no need for secondary processing, effectively improve the qualified rate of finished products;

4. Fast welding speed, no noise in operation, greatly improved welding efficiency, and significantly shortened product welding time;

5. Binocular microscope, ergonomic design, long-term observation is not easy to fatigue;

6. One screen can realize welding parameter adjustment, spot positioning, effect observation, easy to operate, intuitive observation.

Applications:

Specializing in jewelry, precision hardware, watch and clock industry design,mainly used in jewelry, hardware, electronic components, 3C communication, crafts and other industries repair and welding, all kinds of metal and alloy spot weld pattern, splicing, Mosaic parts and other welding; Such as stainless steel, copper, gold, silver, K gold, etc.. jewelry processing shops, stores, factories or school research laboratories necessary welding tools.

Specifications:

Technical Parameters | |

Laser type |

ND:YAG pulse |

Machine type |

TM-150 |

Laser wavelength |

1064(nm) |

Pulse frequency |

1.0-25Hz |

Pulse width |

0.1-20MS |

Spot range |

0.1-2.5mm |

Laser output power |

150W |

Equipment Power supply |

220V 1Ph 50Hz/20A |

Rated output power |

50/100/150W |

Cooling mode |

Built-in air-cooled integrated water tank |

Observation mode |

HD Microscope ICCD integrated |

Dimensions(L*W*H) |

510*290*420MM |

Weight |

40kg |