- Overview

- Recommended Products

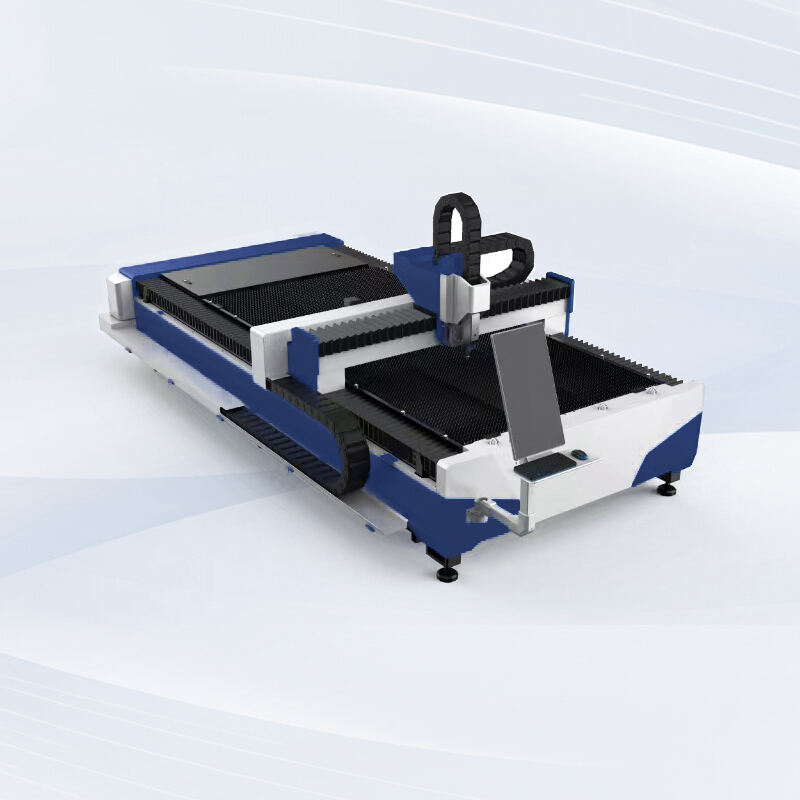

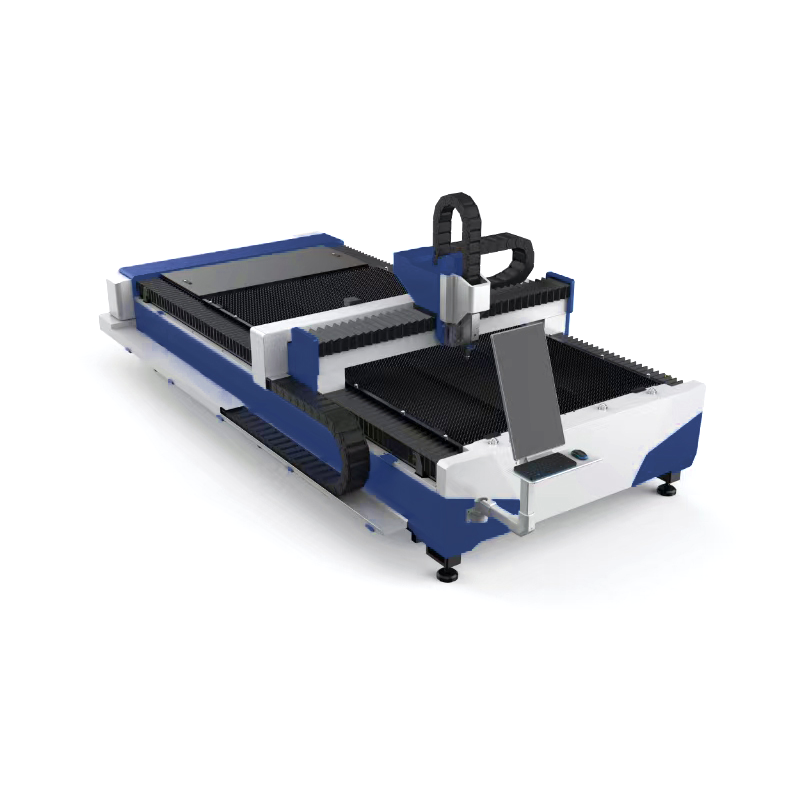

Product introduction:

The S3015 Single-Table Fiber Laser Cutting Machine is a high-power CNC fiber laser cutting system designed to meet international standards of precision and performance. By integrating cutting-edge fiber laser technology with a high-accuracy CNC control system, it delivers high-efficiency cutting solutions for a wide range of metals, including carbon steel, stainless steel, aluminum alloys, galvanized steel, electrolytic plates, silicon steel, titanium alloys, and galvalume sheets.

With its exceptional cutting precision, smooth edge quality, and optimized production efficiency, the S3015 ensures superior processing results even under the most demanding industrial conditions.

Key Advantages:

1. Equipped with a 3000w fiber laser source, the 3000W model (sample) can cut 20mm carbon steel, 12mm stainless steel, and 10mm aluminum quickly and cleanly, maintaining excellent edge quality and processing stability — ideal for various industrial applications.

2. Rollers are installed on three sides of the platform, making material loading and handling more convenient.

3. The crossbeam is made of high-grade aerospace aluminum alloy through an integrated extrusion process, ensuring a lightweight structure, high precision, and fast dynamic response.

4. The single-table working area offers a spacious 1500 × 3000 mm platform with a positioning accuracy of ±0.03 mm, specifically designed for efficient and reliable processing of medium-sized metal sheets.

Applications:

This laser cutting machine efficiently processes a wide range of metal materials, including carbon steel (up to 20mm), stainless steel (up to 12mm), aluminum alloy (up to 10mm), galvanized steel, electrolytic plate, silicon steel, titanium alloy, and more. With outstanding cutting precision and smooth edge quality, it is widely used in machinery manufacturing, sheet metal processing, automotive parts, home appliances, electrical equipment, architectural decoration, and aerospace industries, providing high-quality and high-efficiency metal cutting solutions for diverse industrial applications.

Specifications:

Processing width and working range | |

Processing dimensions |

3000mm*1500mm |

X-axis travel |

1524mm |

Y-axis travel |

3050mm |

Z-axis travel |

100mm |

X, Y-axis positioning accuracy |

±0.05mm/m |

X, Y-axis repeatability |

±0.03mm |

X-Y Axis Synchronized Speed |

100m/min |

X-Y Axis Coordinate Acceleration |

1G |

Number of power phases |

3 |

Rated Voltage of Power Supply |

380V |

Frequency |

50Hz or 60Hz |

Maximum Workbench Load Capacity |

1000kg |

External Dimensions |

4530*2280*1310mm |