- Overview

- Recommended Products

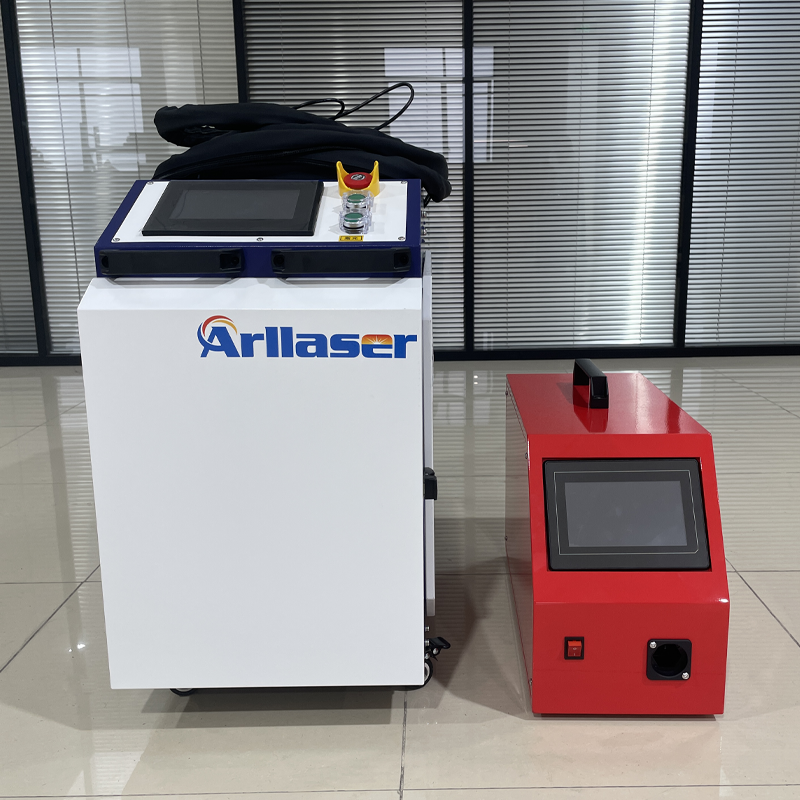

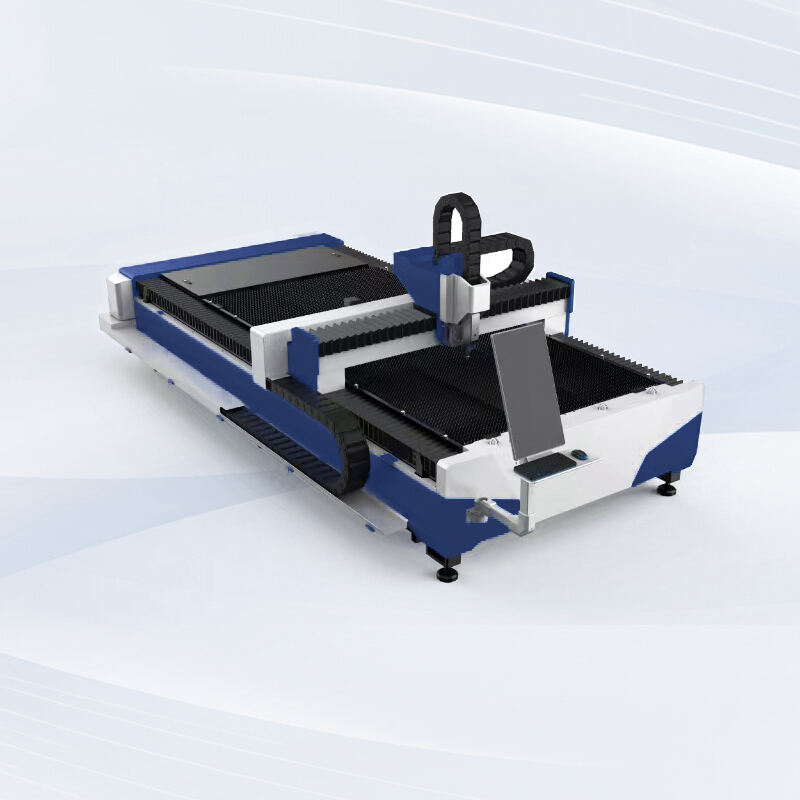

Product introduction:

The laser robot processing system is an intelligent mechanical and electrical products integrating the six axis linkage, high flexibility and low cost of 3D robot. It can be used for welding, cutting, cladding and heat treatment of 3D space components with the application of fiber lasers. With highly flexible design, fiber laser robot processing system is widely used in various fields.

Key Advantages:

1. The six-axis robotic system enables full six-axis linkage, allowing for any trajectory motion to meet a wide range of automated welding requirements.

2. Featuring high welding speed, it supports material thicknesses from 0.3mm to 8mm. The process ensures a small heat-affected zone, minimal deformation, and smooth, aesthetically pleasing weld seams.

3. The robotic laser welding system is maintenance-free, highly efficient, and exceptionally stable, with a service life of up to 100,000 hours. Its total power consumption is only one-eighth that of traditional YAG laser welders, TIG welding, butt welding, or plasma welding systems.

4. Designed for ease of operation, the system comes with a comprehensive laser welding process package that simplifies complex welding tasks, reduces labor costs, and doubles production efficiency.

Applications:

Applicable Materials: Carbon steel, stainless steel, alloy steel, aluminum and alloys (copper and alloys, titanium and alloys,nickel-molybdenum alloys) and dissimilar metal parts. (Copper-nickel, nickel-titanium, copper-titanium, titanium-molybdenum, brass-Copper)

Applicable Industries: Manufacturing, metallurgy industry, automobile industry, electronic industry, biomedicine, household appliances manufacturing, processing tools, IT manufacturing, food machinery, diamond tools, welding, welding gear, surface treatment of metal materials, decorative advertising, laser processing services and other processing machinery manufacturing industry.

Specifications:

Technical Parameters | |

Laser wavelength |

1070±10nm |

Working mode |

Continuous/pulse |

Suggested welding thickness |

0.3-8mm Stainless steel/carbon steel: 0.3-8mm |

Requirements for welding gap |

<0.5mm |

Repeat positioning accuracy |

±0.05mm |

Aiming and positioning method |

Red light indication (CCD optional) |

Power of the entire set of equipment |

10-30kW |

Working voltage |

AC220V/380V 50-60Hz |

Optional power |

1500W-2000W-3000W-6000W |

Spot size |

0.2mm-5mm(Adjustable) |

The length of the mechanical arm |

1.4m, 1.6m, 1.8m, 2.0m(Optional) |