- Overview

- Recommended Products

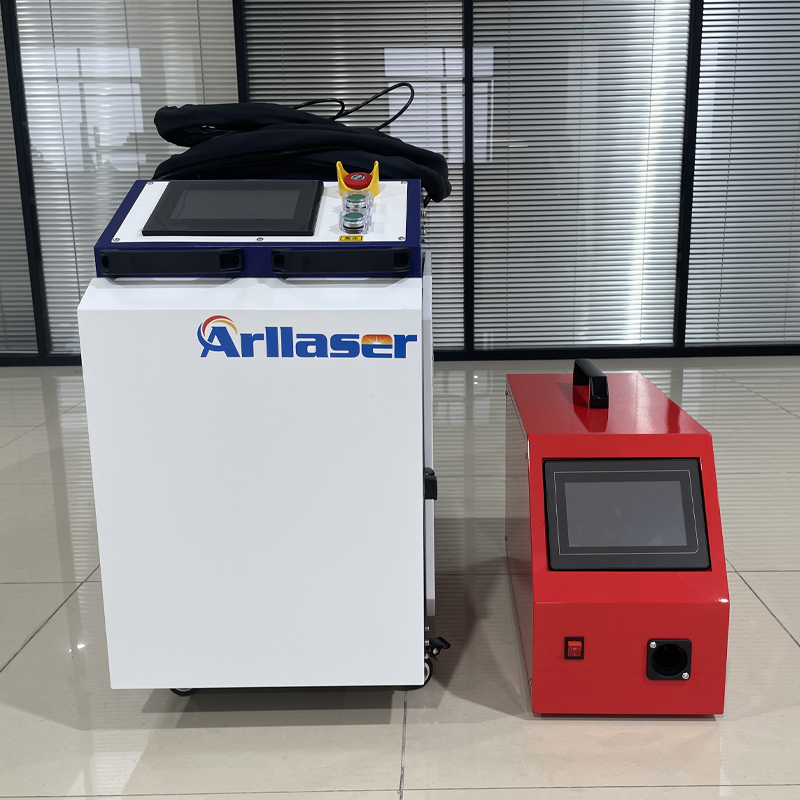

Product introduction:

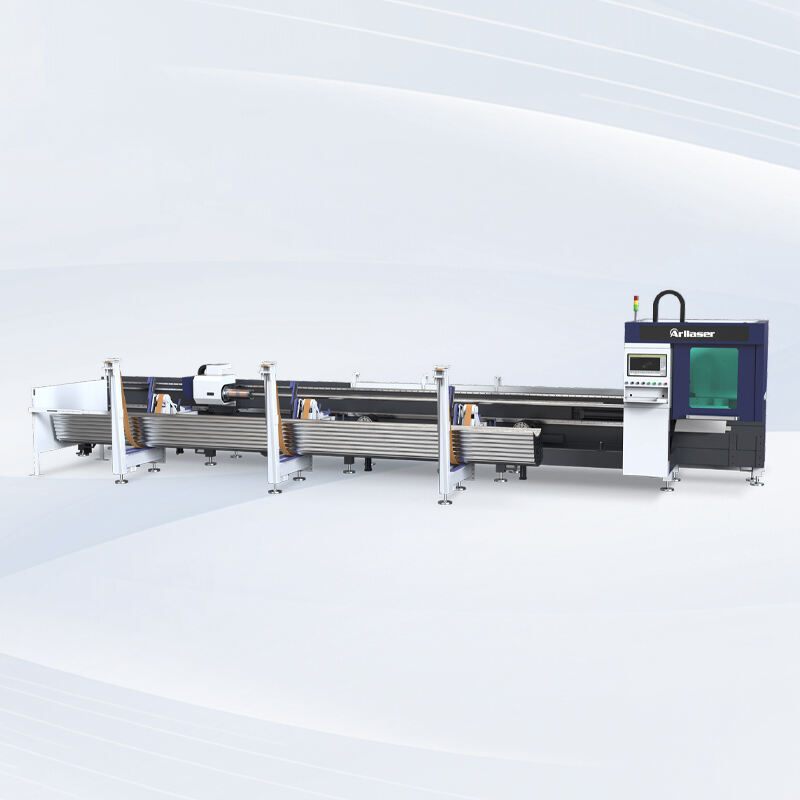

The Six-Axis Automatic Platform Laser Welding System is an advanced welding solution that integrates high precision, superior flexibility, and intelligent automation. Featuring a six-axis linkage control platform, it enables complex spatial welding with multiple angles and trajectories, ideal for various metals and irregular-shaped components.

Equipped with a high-power fiber laser source and an intelligent control system, it delivers smooth, aesthetically consistent welds with minimal heat-affected zones and low distortion. The system’s automated positioning and motion control technology ensures high welding speed, exceptional stability, and consistent quality — significantly improving productivity while reducing labor costs.

Key Advantages:

1. Welding conventional small hardware parts and special-shaped parts (customizable tooling fixtures);

2. All functions are controlled by software and highly integrated;

3. High stability, output power fluctuation <3% at full load;

4. With red light guide;

5. Reserve the expansion I/O interface, which can cooperate with the linkage work of the electrical automation device;

6. Equipped with a pendulum welding head, which can perform spot, straight, circular, and other pattern welding methods;

7. Easy to operate and free of maintenance;

8. The laser welding equipment is mainly composed of fiber laser, single pendulum welding head, precision module, light guide system, cooling circulation system, red light indicator, CCD image monitor system, and all-aluminum plate precision cabinet.

Applications:

The system is applicable to a wide range of metal materials, including stainless steel, carbon steel, iron plate, aluminum, copper, alloy steel, and galvanized sheets. It efficiently handles complex and irregular welding tasks with exceptional precision and stability.

It is widely used in sheet metal fabrication, automotive parts, precision instruments, aerospace, electronics, and new energy equipment, as well as in the production of cabinets, kitchens and bathrooms, staircases and elevators, shelves, ovens, stainless steel doors and window railings, distribution boxes, and stainless steel appliances.

Specifications:

Technical Parameters | |

Equipment name |

Six-axis platform laser welding machine |

Laser power |

1000-3000W |

Laser wavelength |

1080±5nm |

Power range |

1-100% |

Modulation frequency |

(Continuous/modulation)20-50KHz |

Power stability |

≤ 3% |

Work repeat positioning accuracy |

±0.02mm |

Beam quality |

1.1/1.3/1.4/2.1-2.7m³ |

Red light positioning |

Have |

Weld width |

0.3-4mm(Adjustable) |

Fiber output interface |

QBH or customized output |

Powered by |

220V or 380V(According to power) |

Operating temperature |

10-40℃ |

Operating system |

Six-axis laser welding motion control system |

Fiber optic cable |

15m |

Effective itinerary |

X-axis=500mm, Y-axis=300mm, Z-axis=300mm, A-axis= Rotating shaft (optional) |

Motion axis |

4-axis |

Maximum power consumption |

≤ 14kW(According to optional power) |

Total weight |

About 400kg |

Dimensions |

1750*1200*1700mm |