- Overview

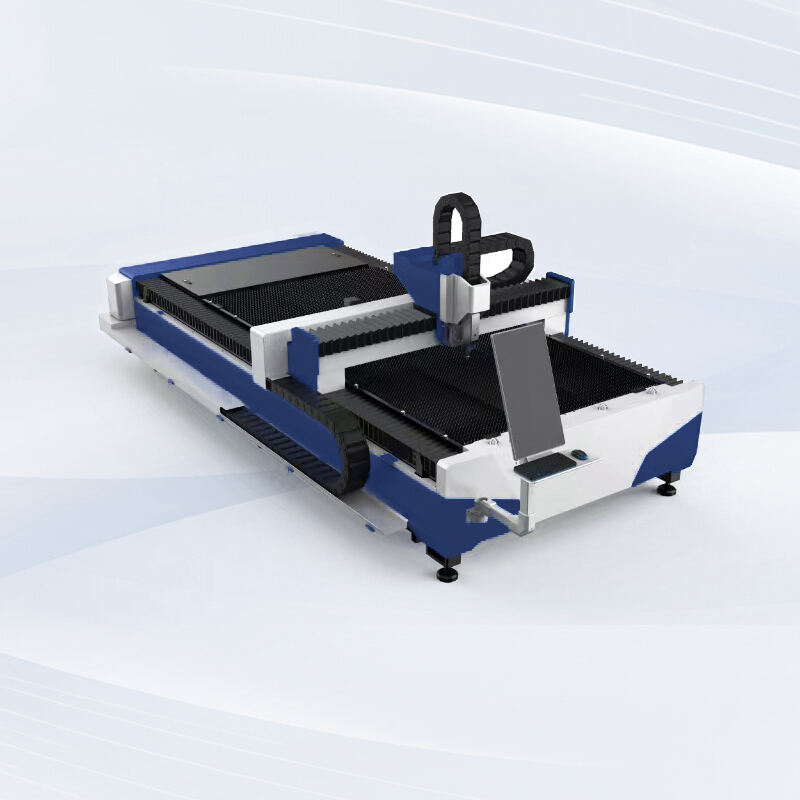

- Recommended Products

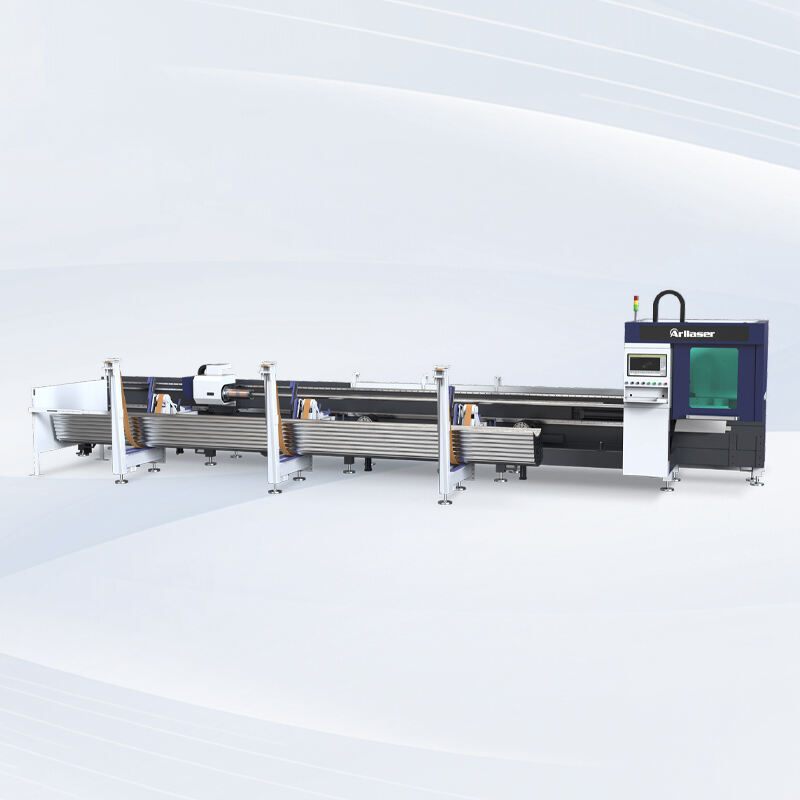

Product introduction:

The G170K Fully Automatic Bevel Laser Tube Cutting Machine is specially designed for high-precision 45° tube cutting, with laser power options ranging from 1500W to 3000W. Equipped with an automatic loading and unloading platform, it ensures structural stability, enhanced load capacity, and superior impact resistance — all contributing to higher productivity and reduced labor costs.

Key Advantages:

1. The machine features a fully automatic feeding rack, saving time and labor with a simple structure and easy operation.

2. Cutting efficiency is 5 to 6 times higher than that of a conventional tube cutting machine.

3. Minimal tailing blind zone helps save material and reduce subsequent processing steps.

4. Residual tail length can be precisely controlled—even reduced to zero—greatly minimizing material waste.

5. Post-cutting capability: The standard configuration includes an integrated height adjuster, allowing for easy cutting of irregular or special-shaped tubes. to 3000W. Equipped with an automatic loading and unloading platform, it ensures structural stability, enhanced load capacity, and superior impact resistance — all contributing to higher productivity and reduced labor costs.

Applications:

The G170K 3D Five-Axis Automatic Bevel Laser Tube Cutting Machine has been widely adopted in industries such as hardware furniture, industrial manufacturing, automotive components, mobile phone brackets, and medical devices, delivering efficient, intelligent, and precise cutting solutions for various tubular metal processing applications.

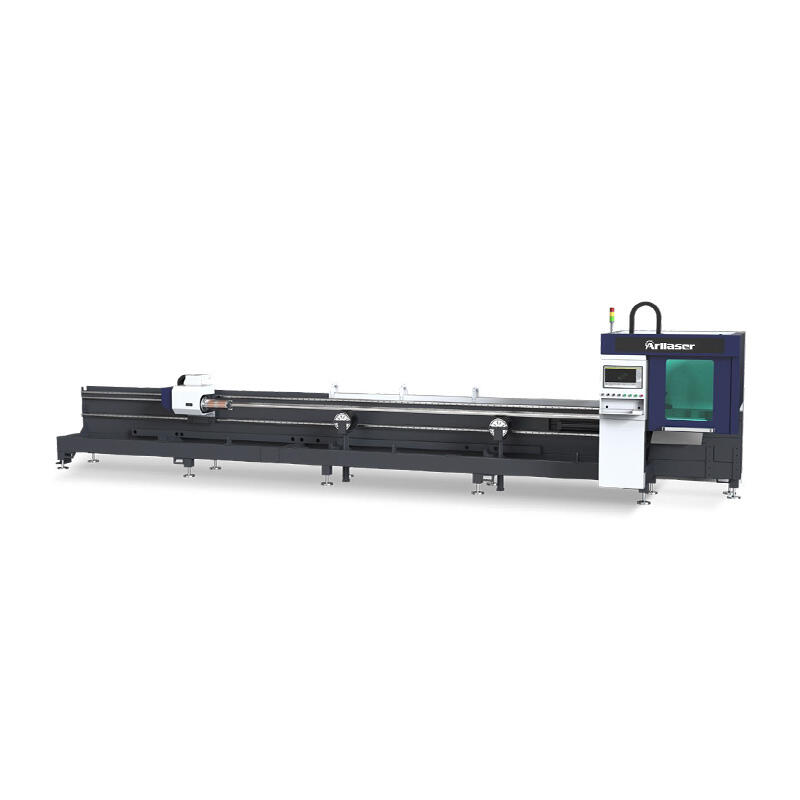

Specifications:

Technical Parameters | |

Model |

G170K |

Laser Power |

1500/2000/3000W |

Cutting range |

Circumference:10-170mm |

Repeat positioning accuracy |

±0.02mm |

Pipe length range |

≈6250mm |

Machine size |

L*W*H:8874*1720*2175mm |

Body + Rack size |

Full Automatic(L*W*H):8874*2949*2175mm |

Machine weight(T) |

≈3.5 |

Acceleration(G) |

≈1.3 |

Tailings length(mm) |

≈80 |