As laser welding technology continues to advance, choosing a high-performance laser welding machine has become crucial for manufacturing enterprises aiming to improve production efficiency, enhance product quality, and strengthen market competitiveness. For businesses, this purchase is not merely acquiring a machine—it is a long-term strategic investment in productivity and product excellence.

Therefore, while price remains an important factor, the decision should also be guided by key dimensions such as equipment stability and durability, welding precision and consistency, and the supplier’s technical support and after-sales service capability. Only reliable equipment paired with dedicated service can ensure consistent and efficient performance in long-term production.

Today, laser welding technology has evolved into multiple types. This article focuses on the key criteria for selecting a reliable water-cooled laser welding machine, helping businesses make a safe and high-value investment decision.

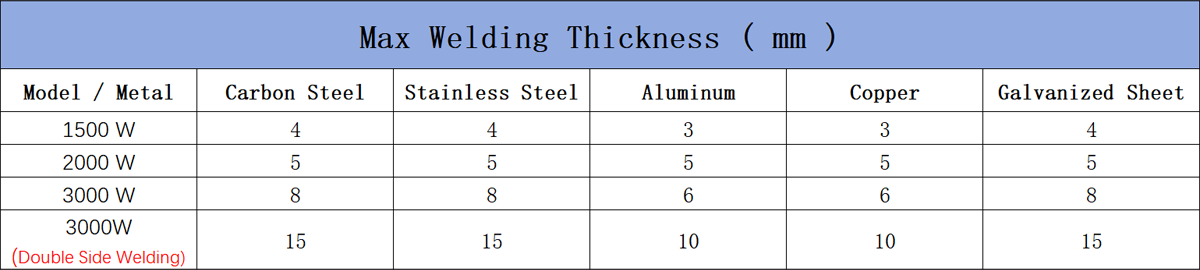

Laser welding machines come in various models and configurations, all designed to meet different industrial needs. Therefore, the first and most essential step in selecting the right machine is to clearly identify the materials and thicknesses you plan to weld in the future. This will directly determine the laser power required.

For example:

If your task is mainly welding 2mm stainless steel, a 1500W laser source is generally sufficient;

For welding 6mm carbon steel, a 2000W laser source is recommended to ensure proper welding strength and efficiency.

For high-reflective materials such as aluminum, it is recommended to choose a laser power of 1500W or above.

By clarifying your specific welding needs, you can avoid both insufficient performance and unnecessary overspending on excessive power.

Figure (1) below shows reference data for maximum penetration depth across different materials at various laser power levels.

A handheld laser welding machine is primarily composed of three core components: laser source, welding system, and water chiller. The quality of these components directly determines welding stability, efficiency, and equipment lifespan.

Laser Source:

The most reputable and widely adopted laser source brands in the market include RAYCUS, MAX, and BWT. RAYCUS and MAX are leading Chinese brands, trusted for their advanced technology and reliable performance. Although BWT has slightly lower brand exposure, it delivers excellent value with solid performance and competitive pricing, earning strong recognition in the market.

Welding System:

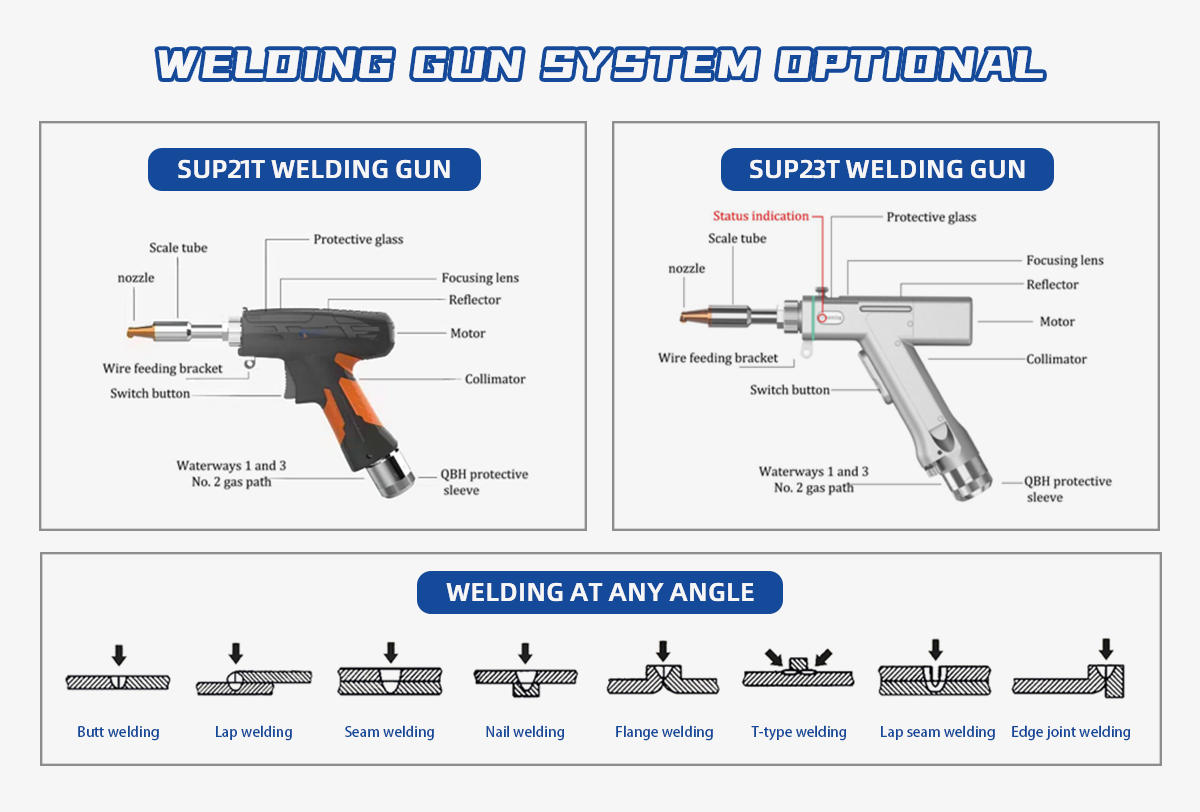

The welding system consists of a control module, welding gun, and wire feeder, and its stability and operating experience significantly influence welding results. Notable brands in the industry include SUPLASER, QILIN, and RELFER. Among them, SUPLASER has become a mainstream market choice due to its outstanding performance and competitive pricing.

The current mainstream handheld welding guns from SUPLASER available on the market are two models: SUP21T and SUP23T, as shown in Figure 3 below.

Water Chiller Brands:

Precise temperature control is essential for maintaining stable welding performance. A high-quality water chiller ensures continuous and reliable cooling for the laser system, enabling long-term, efficient operation. The leading water chiller brands in the current market are HANLI and S&A. HANLI holds strong market recognition and is widely regarded for its reliability, while S&A follows closely behind with excellent performance and a solid reputation among users.

When selecting a laser welding machine, equipment performance is important—but the supplier’s expertise and service capability are equally critical. A professional supplier can provide valuable guidance based on real-world application experience, helping you make the right decision and operate the machine efficiently. Meanwhile, strong after-sales support ensures timely assistance when issues arise, preventing production downtime and guaranteeing stable operations.

At ARLLASER, we prioritize customer needs throughout every stage—from product development and manufacturing to delivery and after-sales service. We stay closely connected with our clients and respond promptly to any inquiries, offering expert advice and practical solutions to ensure smooth and efficient production.

ARLLASER looks forward to becoming your most trusted partner and supporting your success with reliable technology and dedicated service!

Hot News

Hot News2025-11-01

2025-12-03

2025-12-01

2025-11-25