Thank you for choosing ARLLASER handheld fiber laser equipment. After receiving the handheld laser welding machine or cleaning machine, please check that the outer packaging is intact. Once the machine arrives, please contact us immediately to arrange technical support and commissioning.

1. Precautions Upon Product Arrival

1) Keep at least 20 cm of ventilation space at the front and rear of the equipment.

2) Do not place flammable or explosive items near the equipment.

3) Before use, fill the machine with purified water or distilled water (add antifreeze in winter!). It is strictly forbidden to power on or operate the machine without coolant.

4) Be sure to connect to an air circuit breaker. Do not use extension cords or power strips.

5) During testing and operation, shielding gas must be turned on. It is forbidden to operate without shielding gas.

6) For welding, prepare welding wire that matches the workpiece. For aluminum, aluminum-magnesium alloy wire ER5356 is recommended.

7) When operating or moving the equipment, handle the laser head carefully to prevent dust from entering and causing contamination.

8) Wear protective goggles and a mask during operation and ensure proper safety protection.

9) The temperature difference between the chiller water and the ambient temperature must not exceed 10°C. In summer, keep the water temperature at 26–30°C; in winter, 20–22°C. Excessive temperature differences in the cabinet may cause condensation on laser components, resulting in laser damage.

10) Antifreeze must be used when the ambient temperature is below 4°C.

11) Do not excessively bend or step on the optical fiber cable.

12) Do not share grounding with arc welders, argon arc welders, electric welders, or CO₂ shielded welding machines to prevent current backflow that may affect laser components.

13) Never aim the laser head at any part of the body during operation.

14) Do not place the laser head on the ground; pay attention to dust protection.

15) In case of any emergency, immediately press the emergency stop button.

16) When the equipment is not in use, be sure to cover the laser output port. Dust on the output end of the handheld head may damage the protective lens, resulting in reduced output power or no laser output.

17) Before cleaning or maintaining the equipment, ensure that the machine is powered off.

2. Machine Operation Instructions

First, fill the chiller with water (purified water or distilled water). Fill until the water level reaches the standard range. (Note: Add laser antifreeze in winter.)

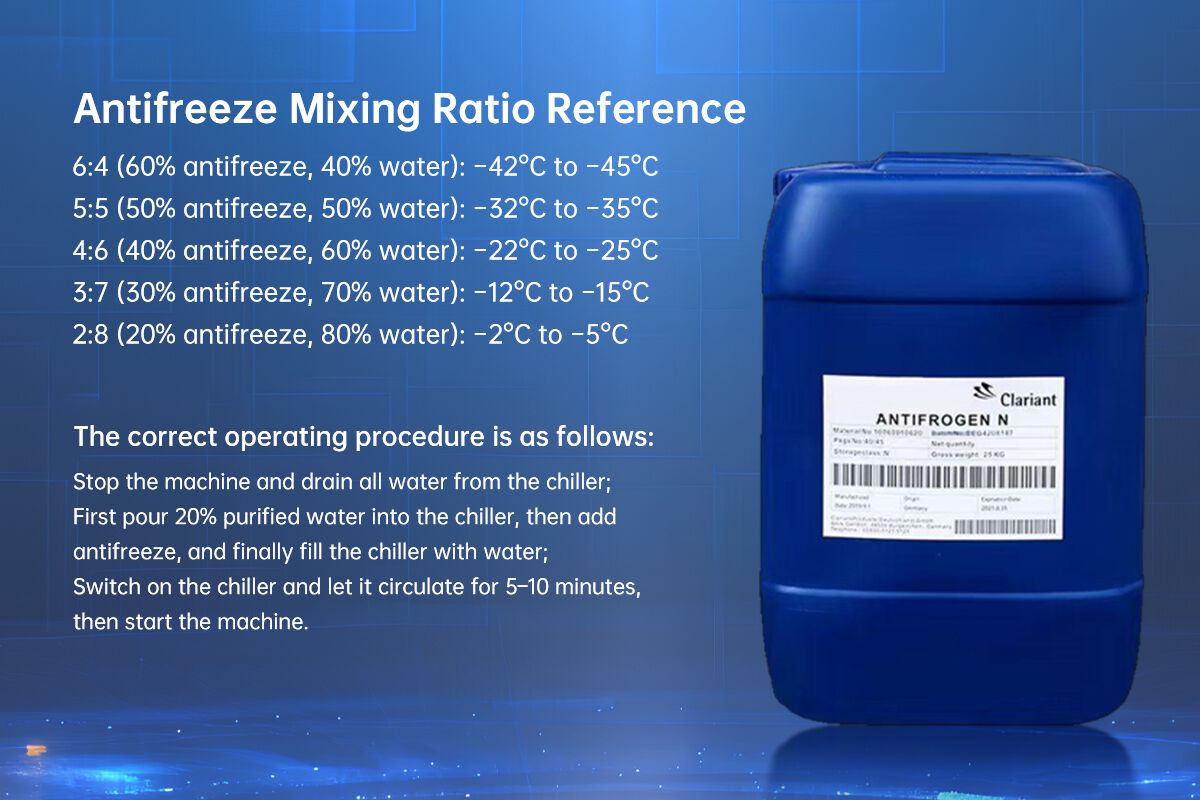

Antifreeze Mixing Ratio Reference:

Because the laser antifreeze is highly concentrated, incorrect operation by beginners may trigger laser alarms.

The correct operating procedure is as follows:

Connect N, L, and PE to the external power supply neutral wire, live wire, and ground wire respectively.

3. Machine Installation and Commissioning Steps

1) Turn on the wire feeder, install the wire spool, and secure it. Connect the welding wire, open the fixing handle, feed the wire through the wire guide, then press it firmly. Next, press the manual wire-feed button on the wire feeder panel (until the wire reaches a suitable position at the torch head).

2) Connect the gas hose and increase the gas pressure to 0.5 MPa.

3) Check the water tank temperature and confirm that the actual water temperature is within the set range. (In winter, ensure the chiller temperature reaches above 20°C.

4) Open the protective lens cover of the laser gun and check whether the protective lens is worn or damaged.

5) Adjust the laser focal length (observe the size of the welding spark and rotate the scale tube; when the spark is at its largest, the setting is optimal for welding).

1) Handle the welding gun with care; do not drop it.

2) If the laser output suddenly becomes weak during normal use, do not increase the power immediately. First check the lens. If the red light is not visible or is misaligned, do not emit the laser.

3) If any abnormal condition occurs during operation, please record a short video describing the problem and contact us. We will assist you in troubleshooting and resolving the issue as soon as we receive your message.

Hot News

Hot News2025-11-01

2025-12-03

2025-12-01

2025-11-25