Thank you for choosing ARLLASER. Upon receiving the machine, please carefully read this safety manual before installation. Be sure you understand laser hazards and related electrical risks, take the necessary protective measures, and maintain proper safety awareness. Safety is the foundation of production — ARLLASER wish your operations a smooth and safe run!

The handheld laser welding machine is a Class 4 laser product which can produce dangerous and invisible laser radiation.The product has infrared laser radiation with a wavelength of 1080nm and an average power of more than 100W from the welding torch,which may cause direct or indirect damage to eyes and skin exposed to such laser intensity.The infrared laser radiation is invisible and the laser beam may cause irreversible damage to retinas or corneas of human eyes.Before operation of the handheld laser welding machine,the operator must wear a pair of laser protective goggles which has been certified and is suitable for the1080nm near-infrared band.

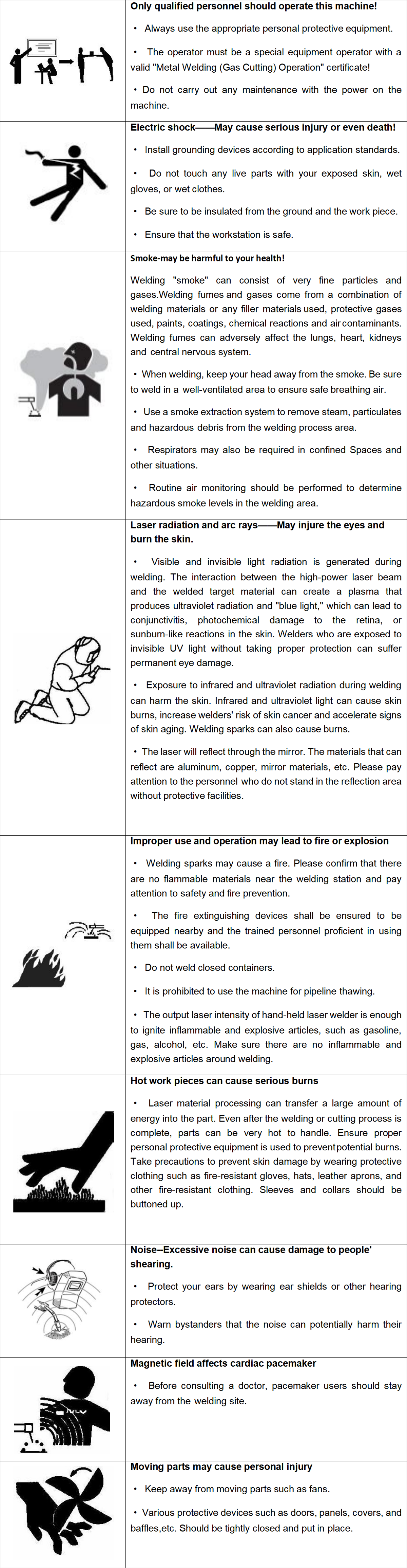

1) For your and others' safety, it is strictly forbidden to point the welding torch at yourself or others;

2) Before use of the handheld laser welding machine, the operator must wear a pair of laser-light protective goggles certified and suitable for the 1080nm near-infrared band and a pair of heat-resistant protective gloves;

3) To ensure your and others’ safety, you must attach the safety earth clamp to the welding work piece before activating the laser. It is prohibited to use the clamp to hold other parts other than the work piece, avoiding any safety hazards due to abnormalities in the laser output;

4) The operation of the handheld laser welding machine should be performed in a separate room provided with laser protection measures. During its use,the non-welding workers, combustibles, and inflammable should be at a distance of more than 10m from the welding bench.Furthermore, fire extinguishers should be put in the vicinity of the welding area;

5) The operator should wear a mask when welding the highly reflective materials;

6) Ensure that the handheld laser welding machine is earthed properly; if not, there may be a live current on the machine's housing, resulting in personal injury to the operator.If the machine’s earthing is not in accordance with the requirements, hidden failures may result, such as laser device alarm, no laser,and laser instability;

7) Do not work in the rain or direct sunlight. Otherwise, an alarm or a short-circuit problem may result from high temperature and humidity, influencing normal operation of the laser device or even causing potential safety hazards.

Handheld laser welding machines are Class 4 laser products, which have high output power and may cause a great hazard to the human eyes and skin. During work, workers should take safety measures for the laser products. Also, the working areas should be provided with safety measures to prevent personnel from any hazards by laser radiation. When protective measures fail the requirements for this protection degree, reasonable and practicable methods can be adopted, such as enclosing the processing area and providing interlocking protection,etc.,to limit the laser radiation hazards and other hazards to which personnel are exposed to a specific extent.The laser radiation exposure for personnel should not exceed The maximum permissible exposure(MPE) specified in GB7247.1 and the limit requirements outlined in GBZ2.2 for a radiation duration of 3×104 seconds.

Safety engineering control measures should include:

1) Engineering control measures: engineering protection measures that are integrated by customers around the laser equipment (such as enclosed working room, safety protection fences,etc.).

2) Management control measures: comprehensive management policies, procedures, and use and display of hazard warning signs, training and guidance, and job responsibilities and prohibitions.

3) Personal protective equipment: protective equipment worn by working personnel, which mainly refers to laser protective goggles, but also includes special protective clothes and protective gloves used to protect the skin, as well as respiratory protection apparatuses used to protect against metal vapor,dust, and smoke, and earplugs used to protect against excessive noise level.Before use of the handheld laser welding machine,the operator must wear a pair of laser-light protective goggles certified and suitable for the 1080nm near-infrared band and a pair of heat-resistant protective gloves.

At the customers' working site, it is required to establish a laser-controlled area and set up protective fences.

The laser controlled area is an area where laser beam hazards exist and a certain degree of effective hazard control measures should be taken.Thus,only designated personnel who have received sufficient safety training and controlled personnel can enter this area.

The working site should be set up with protective fences to separate the working area according to the hazard level. The fences should be able to withstand the laser radiation without any intervention and prevent personnel from accidental exposure to a radiation level higher than that of Class 1 laser products.

No flammable or explosive articles should be stored at the working site.

Users must be aware of the hazards they may encounter and the necessary protective measures adopted during the use of the laser equipment. Users should appoint a laser safety officer to manage the enterprise’s daily affairs about laser safety.

The laser safety officer’s responsibilities include at least:

1) Knowing all information about potentially hazardous laser products (including identification certificates, instructions, classification and usage of laser products; location of laser products; any special requirements and restrictions related to the use of laser products) and keeping their relevant records.

2) Supervising compliance with the organization’s procedures formulated to ensure the safe use of laser products, maintaining appropriate written records, and in the event of any violation of procedures and obvious noncompliance with safety procedures, immediately stopping and taking appropriate actions.

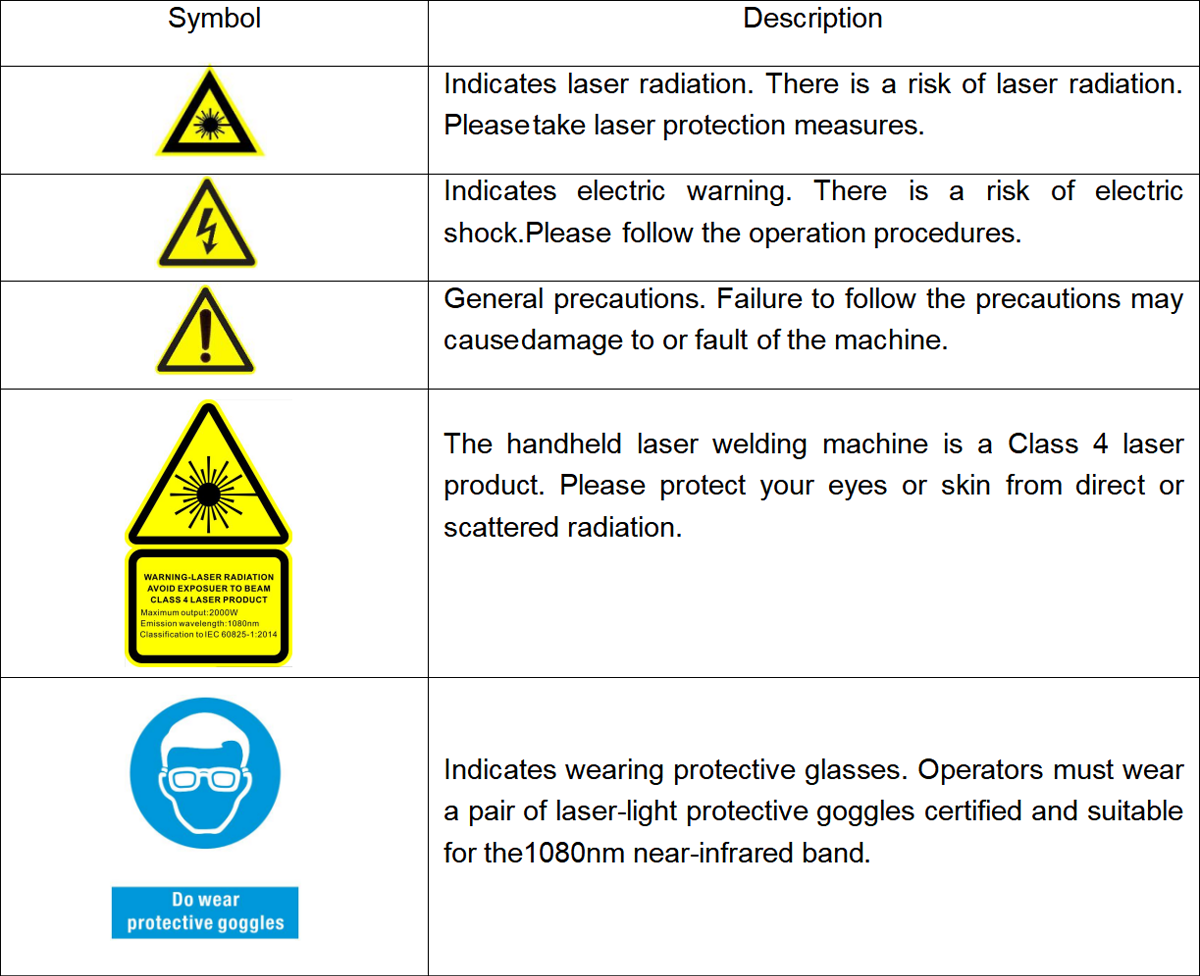

All safety warning symbols involved in the operation process of handheld laser welding machine include:

If, after reading this manual, you still do not fully understand its contents or are unable to resolve the problem according to the instructions in this manual, please contact ARLLASER immediately for professional assistance.

Hot News

Hot News2025-11-01

2025-12-03

2025-12-01

2025-11-25