1. Use of the copper nozzle

The classification of copper nozzles is mainly based on whether wire feeding is used, the wire diameter, and the welding angle, as shown in the figure above.

For example, for inside-corner welding with wire feeding using 1.0 mm welding wire, an AS-12 copper nozzle should be used.

2. Selection of Welding Wire

Depending on the material being welded, different welding wires (gas-shielded solid wires) must be used:

Stainless steel requires stainless steel welding wire, such as ER304.

Carbon steel/galvanized sheet requires carbon steel welding wire.

Aluminum materials require aluminum welding wire (we recommend using 5-series and above aluminum alloy wire, which has higher hardness and is less likely to jam).

3. Selection of Shielding Gas

The two common options are nitrogen and argon. For welding stainless steel, we recommend using nitrogen, as it provides better welding results. Do not use mixed gases or carbon dioxide.

Gas supply requirements: the flow meter should be set to no less than 15 L/min, and the pressure gauge should read no less than 3 bar.

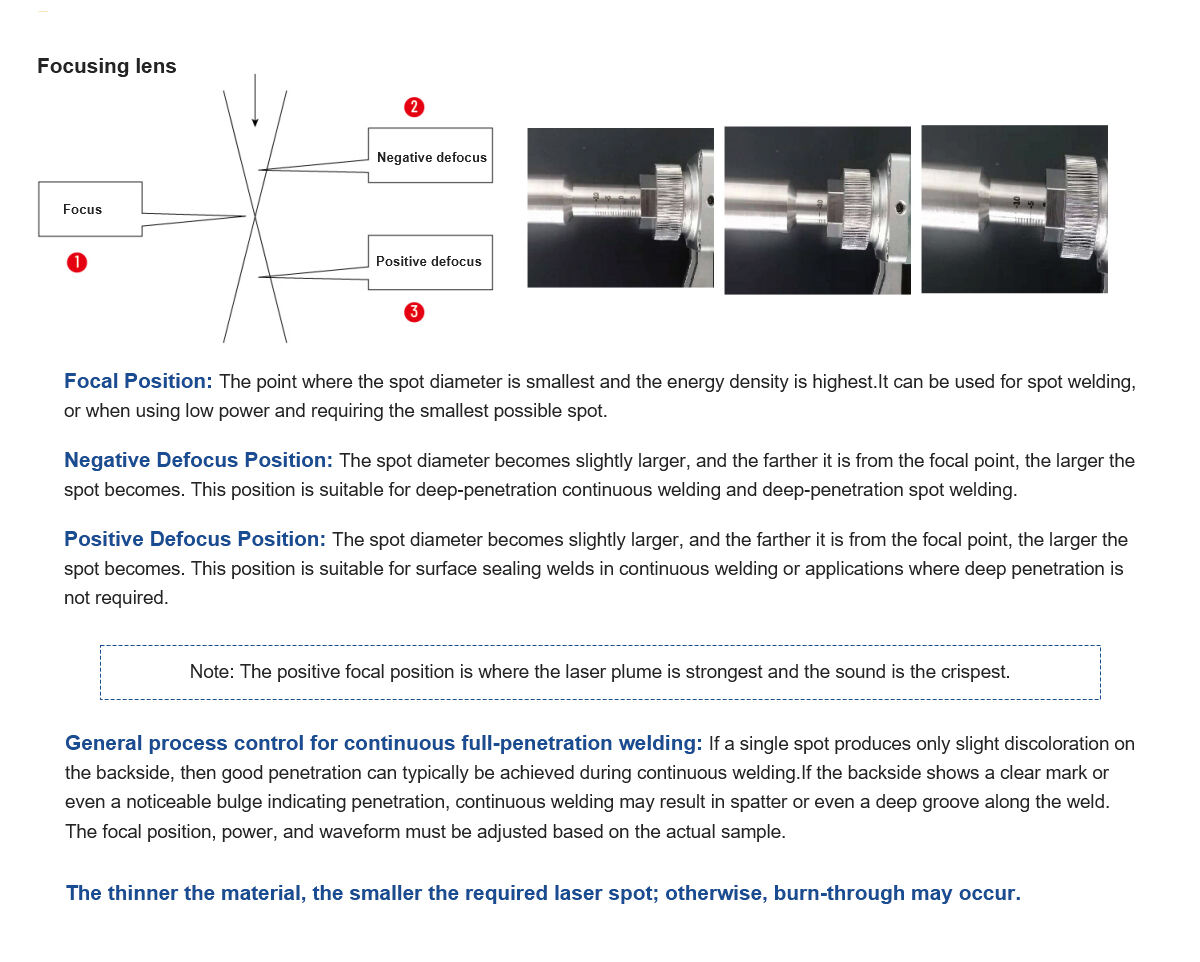

4. About the Focal Position

Note: different machine models use different graduated tubes!

Under normal circumstances, welding is performed at the ”0” position on the scale tube (note that the ”0” mark on the scale tube does not represent an actual focal distance of zero; the initial laser characteristics may affect this, so the actual focal point should prevail).

Hot News

Hot News2025-11-01

2025-12-03

2025-12-01

2025-11-25